Wahl has a number of precast refractory solutions for steel and iron ladles to improve safety, refractory life, ladle availability and yield.

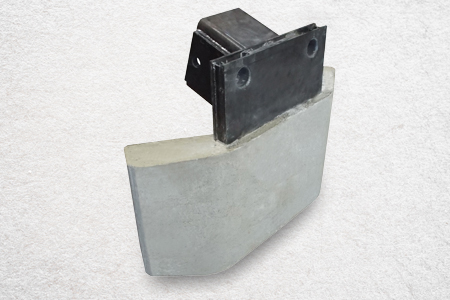

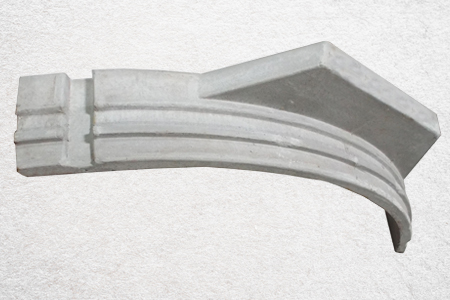

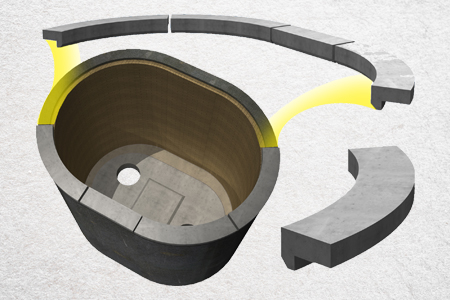

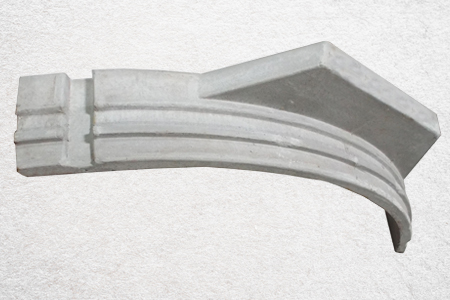

LADLE LIP RETENTION SYSTEMS, SPOUT LINERS & SPOUTS

- Ladle lip retention systems and spouts can be designed to accommodate any ladle shapes.

- Wahl’s ladle lip retention systems and spouts offer ease of installation with a bolt-on design, utilizing a steel bench plate combined with Wahl’s SIFCA® ladle lip rings.

- SIFCA® stands up well to the mechanical abuse and thermal shock.

- Spout liners protect the ladle’s steel shell from molten metal penetration.

- Precast spouts help with brick compression and provide a controlled pouring location.

LADLE LIP RETENTION SYSTEMS, SPOUT LINERS & SPOUTS

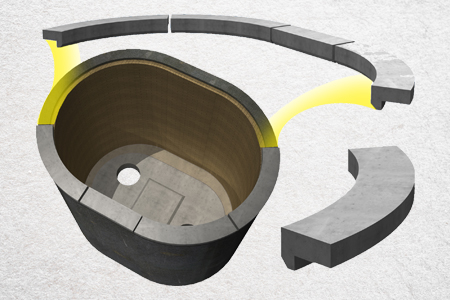

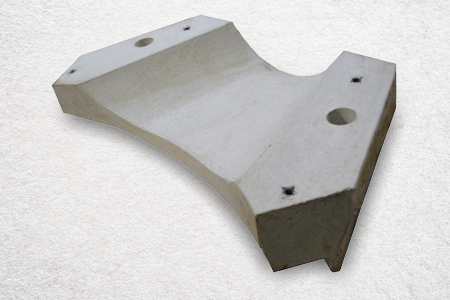

LADLE BOTTOMS

- Wahl’s one-piece ladle bottoms offer speed of installation and lower labor costs by eliminating brick.

- Impact pad can either be designed as part of the precast working ladle bottom or as a separate precast shape.

- Starter course bottoms and precast material zoning capabilities create cost effective solutions for harsh operational conditions.

- Safety bottoms provide protection against breakouts and can be precast or cast-in-place.

PRECAST WORKING BOTTOMS/IMPACT PADS

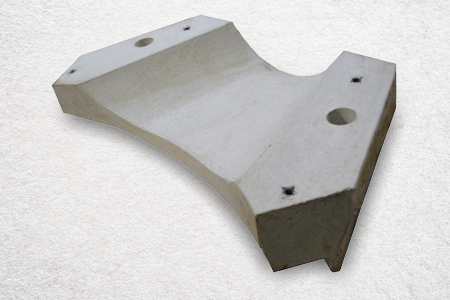

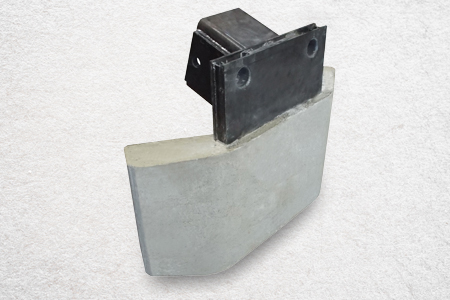

IRON & STEEL SKIMMERS

- Wahl determines which refractory material is optimal depending on the severity of the application.

- Outlast the conventional refractory, steel and cast iron skimmers.

- Exhibit extreme thermal shock resistance and mechanical strength.

- Longer life leads to a cost effective solution.

IRON & STEEL SKIMMERS