FURNACE DOOR LININGS

- One component or multiple component linings available.

- Precast perimeter, interior or cast-in-place panels.

- Doors and anchoring system are designed to withstand elevated temperatures.

FURNACE DOOR LININGS

FURNACE DOOR PERIMETERS

- Ability to zone precast materials between jamb, lintel and sill.

- “Ultra” products, no-wire, low-wire, WireMaxXx® and SIFCA® available.

- Command™, GemStone® and other materials available.

FURNACE DOOR PERIMETERS

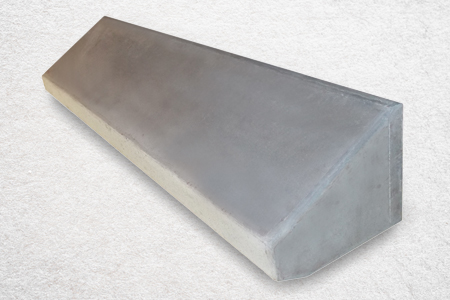

SILLS

- “Ultra” products, no-wire, low-wire, WireMaxXx® and SIFCA® available.

- Excellent impact and erosion resistance.

- Material selection considered based on furnace alloy.

- Precast shapes can be custom configured for your applications.

- Precast shapes reduce installation and dry-out time for maintenance.

SILLS

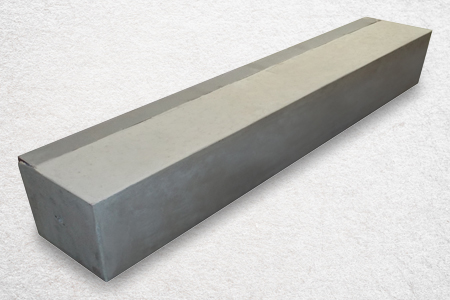

JAMBS

- “Ultra” products, no-wire, low-wire, WireMaxXx® and SIFCA® are available.

- Excellent impact resistance.

- Precast shapes can be custom configured for your applications.

- Precast shapes reduce installation and dry-out time for maintenance.

JAMBS

LINTELS

- “Ultra” products, no-wire, low-wire, WireMaxXx® and SIFCA® are available.

- Excellent impact resistance.

- Precast shapes can be custom configured for your applications.

- Precast shapes reduce installation and dry-out time for maintenance.

LINTELS

ARCHES

- Arches have been designed to nearly 25,000 pounds.

- “Ultra” products, no-wire, low-wire, WireMaxXx® and SIFCA® are available.

- Custom configured for your application.

- Reduce installation and dry-out time.

ARCHES