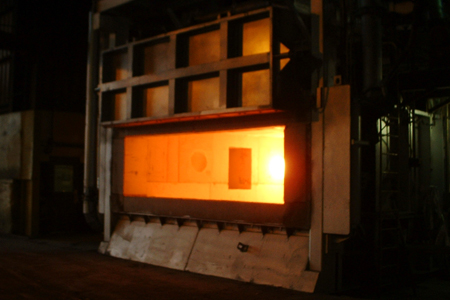

MegaBRIX® is Wahl’s branded name for any full or partial precast furnace. Whether new construction, lining replacement or lining repair, MegaBRIX® Precast Furnace Linings provide superior lining performance, ease of installation and quick turnaround.

- Extensive Project management experience within the aluminum industry.

- Ability to utilize local labor or prequalified Wahl contractors.

- Projects range from maintenance repairs to complete installations.

TURNKEY INSTALLATIONS, REPAIR & MAINTENANCE

Upper Walls

- Products range from 60 to 70 percent alumina.

- Can be precast, cast-in-place or shotcrete.

- Good refractory thermal conductivity resulting in low shell temperatures.

Lower Walls

- Products range from 70 to 90+ percent alumina.

- Non-wetting additives are resistant to 2200° F.

- Excellent corundum attack resistance at the furnace belly band.

- Erosion resistant materials available for EMP and Sidewell applications.

UPPER & LOWER WALLS

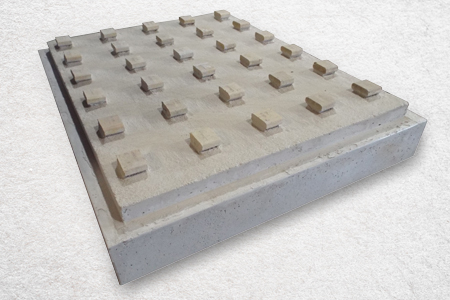

- Modular design allows for fast installation.

- Engineered and designed for individual furnaces.

- Allows for growth and expansion during furnace heat up.

ROOFS

ԑMAXXX™ is a patent-pending family of high emissivity solid refractory materials that can be used to provide increased radiant energy. ԑMAXXX™ materials can be used in a wide range of high temperature industrial furnaces. This technology increases the amount of energy transferred through radiation, thereby redirecting energy that would have otherwise been lost through the waste gas as a means of providing a host of benefits such as:

- Increasing production at the same firing rate

- Decrease fuel consumption at the same production rate

- Lowering CO2 and NOX emissions per ton of product

- Increasing process heat recovery rates

- Redistribution of heat flux within a furnace to where its most needed

- Debottleneck a furnace-limited process

The impacts of ԑMAXXX™ on a process can be very substantial and long-lasting.

- Products range from 70 to 90+ percent alumina.

- Erosion resistant materials available for Electro-Magnetic Stirring.

- “Ultra” materials available for impact resistance.

HEARTHS

- Non-wetting insulating castable for back-up lining.

- Precast or cast-in-place.

SUB HEARTHS

- Erosion resistant materials available.

- Non-wetting additives are resistant to 2200° F.

- Wire can be added to minimize thermal shock.

POUR SPOUTS

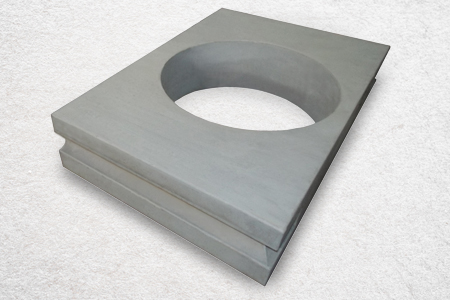

- Engineered furnace openings to ensure proper alignment.

- Material zoning from furnace to breach.

BREACH WALLS

- Erosion resistant materials.

- “Ultra” materials available for impact resistance.

- Non-wetting additives are resistant to 2200° F.

CHARGE WELLS